You are here

Volume 2 - Wet Mill

In our last edition, we explored picking the coffee fruit from the tree. Once that has happened, there is still quite a journey to take before we have any coffee to drink. The next step is to remove the seed from the surrounding layers of fruit and mucilage and to dry the seed (bean). Generally, we call this part of journey cherry processing, though it can be broken down into wet and dry milling. Wet milling is concerned with removing the fruit and muci-lage layers before drying the seed.

As it turns out, there are several cherry processing methods. Each has its pros and cons and most have a noticeable effect on the flavor of the coffee brew. There is discussion as to the best way to process the cherries, but more importantly ... a method should be embraced and done well.

The purpose of cherry processing is to remove all the layers from around the seed and reduce the moisture content of the seed. Those tasks can be done in any order. Of course, there are variations of each of these general methods.

The purpose of cherry processing is to remove all the layers from around the seed and reduce the moisture content of the seed. Those tasks can be done in any order. Of course, there are variations of each of these general methods.

• The oldest method involves drying the entire fruit down, with the seed inside, before removing the seed. This is called the fruit dried, natural process, or dry process.

• Or the seed can be removed from the fresh fruit leaving the other layers (mucilage and parchment) on the seed while it dries. This is called the pulp dried, semi-washed, or honey process.

• Or the seed is removed from the fresh fruit and the mucilage removed with a machine or by fermentation process before the seed is dried. This is called parchment dried, washed process, or fermentation method.

Here at Mountain Thunder, we embrace the washed process/parchment dried. We believe this brings out the seed’s best inherent characteristics. While other methods may add a distinctive flavor that comes from the method itself, we think fermenting the mucilage off the seed best exposes the soul of the coffee to your palate.

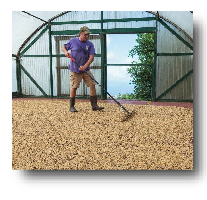

Once we remove the mucilage, we primarily dry the seeds (beans) on open-air decks. It takes 1 - 2 weeks for the seeds to dry down to the appropriate moisture content. However, if our decks are full, we will use custom-built dryers to speed up the drying process.

Once we remove the mucilage, we primarily dry the seeds (beans) on open-air decks. It takes 1 - 2 weeks for the seeds to dry down to the appropriate moisture content. However, if our decks are full, we will use custom-built dryers to speed up the drying process.

Once the coffee, now called parchment coffee, is dried, we store it in a temperature and humidity-controlled environment for several months. We believe this “aging” is critical in attaining the best of the best flavor experience that you expect from Mountain Thunder’s 100% Kona Coffee.

In our next edition, we’ll see what happens in the dry mill where the parchment layer is removed from the seed and we finally see the green coffee beans.